Customised

Solutions

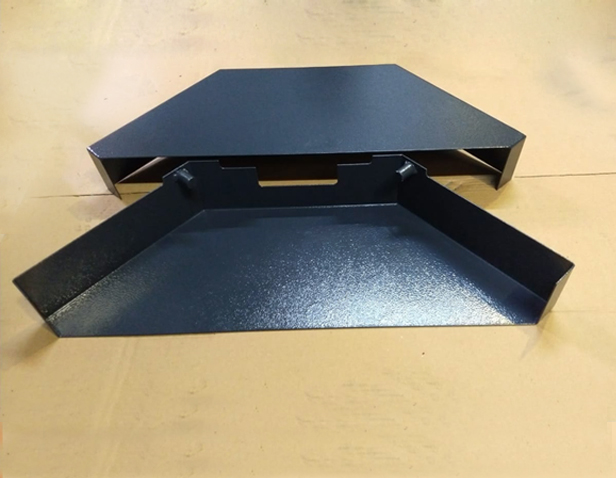

1) Product Development (Custom Engineering for Manufacturing)

Product design has a direct impact on product quality, production costs, and customer satisfaction. Our product development engineers get involved early with customers, assisting in product design for manufacturability and assembly.

Detailed drawings and layouts, bill of material (BOM) development, and process design are core competencies deployed by our product development engineers. This custom engineering support is just a part of what we do for our customers. If you’re looking for support in developing the parts and components to fit your application or your product, our team is available to assist. You’ll work directly with engineers who will provide life cycle support of your products.

Capabilities:

- Assistance in designing your product

- Improve existing design

- Redesign for manufacturability

- Redesign for cost reduction

Software Used:

We employ the “Solid Works” solid modeling package. This gives us a true 3D model that is fully parametric through the part model, assembly, and drawings. To understand the power of our CAD system, please visit the “Solid Works” web-site.

2) Research and Development Services

ALW can produce prototypes faster, more reliably, and often less expensively thanks to our dedicated Research and Development resources. With specific machines, experienced staff, and cutting-edge technology solely dedicated to the front-end work of complicated projects, we can take your ideas from inspiration to implementation.

Dedicated R&D Assets

We have dedicated facility devoted solely to designing, producing, and perfecting prototypes for testing instead of having to wait for a break in the production schedule for your project to move forward.

Our facility houses all the machines necessary to fab, weld, machine and paint most anything imaginable and our R&D staff is dedicated to only this service.

Technology

- Solidworks

- Temporary tooling